Call Us Today! 281-479-8301 | 866-479-8301 | sales@intrepidindustries.com

Houston, Texas | August 17, 2020

If your walking-working surface is elevated more than 4 feet off the ground, your guide to the newly revised OSHA standard is below.

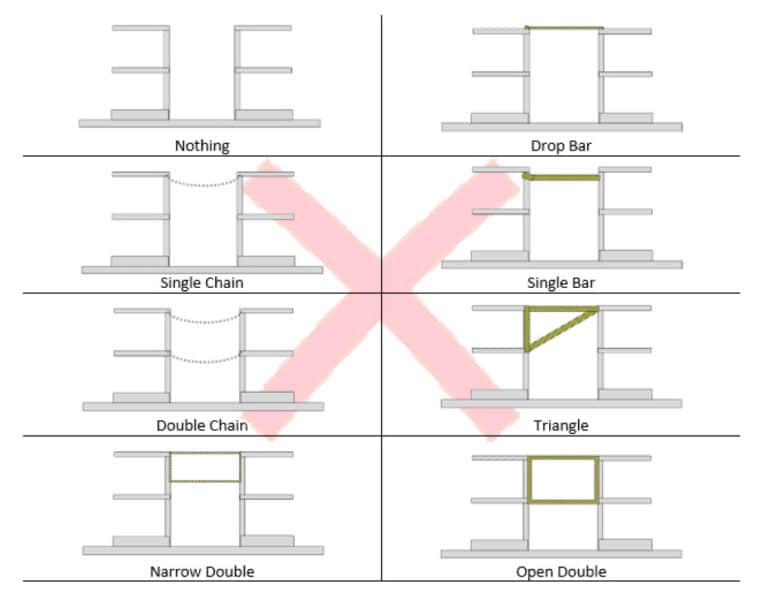

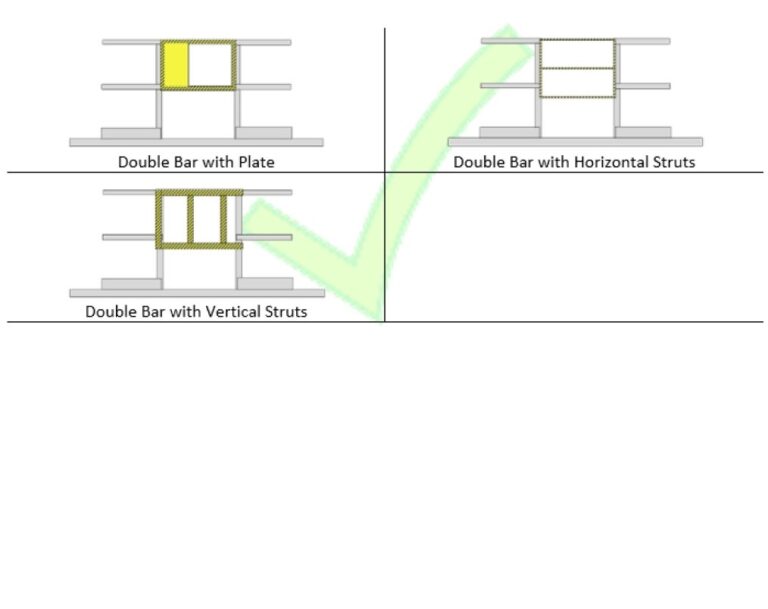

While these illustrations do not include every possibility of what is out there, they do give a good idea of what to look for when replacing and/or purchasing new safety gates. Besides what is illustrated, an additional key feature to note is the gate must be self-closing. This is important because the previous standard only required that it be a swinging gate.

The newest OSHA revisions include the following criteria for OSHA 1910.29 (b): “Fall protection systems and falling object protection — criteria and practices.” The employer must ensure guardrail systems meet the following requirements:

To provide even more insight, below is a simplified list of some key areas to focus on when evaluating your current conditions. These can be used to help you determine the appropriate course of action in and around any holes, openings or current access points with or without safety gates.

OSHA’s standard requires that a safety gate:

For example, if you are currently using chains, single-bar or drop-bar style gates in an access point or opening, they are no longer compliant and need to be replaced. Rusted spring-closing or compression gates no longer capable of self-closing will need repair or replacement. Gravity-closing gates can no longer be held open with bungee cords to prevent self-closure.

Start auditing walking-working surface compliance today. It’s cheaper than letting OSHA do it for you.

The latest OSHA revisions include the following criteria for OSHA 1910.29: “Fall protection systems and falling object protection — criteria and practices.” The employer must ensure guardrail systems meet the following requirements:

For more information regarding this new standard, visit www.intrepidindustries.com or www.osha.gov, call (281) 479-8301 or email Paxton Guidroz at pguidroz@intrepidindustries.com.

Published on BIC Magazine at: https://www.bicmagazine.com/departments/hse/new-osha-safety-gate-standard/.

Time's up

Intrepid Industries Inc.

2305 S Battleground Rd

La Porte, TX 77571

Phone: 281-479-8301 | 866-479-8301

Fax: 281-479-3453

Email: sales@intrepidindustries.com