OSHA Toeboard Requirements:

Protect Your Holes!

Houston, Texas | May 5, 2021 | Updated December 14, 2023

Have you ever looked at an engineering drawing and noticed how nicely everything comes together? Everything is perfect! Unfortunately, during the construction stage, that perfection quickly fades.

At Intrepid Industries, we understand that safety is the bedrock of any successful industrial operation. In the world of manufacturing, construction, and maintenance, the well-being of our workforce and providing falling object protection is of the utmost importance. This is why we take safety seriously, and so does the Occupational Safety and Health Administration (OSHA).

Safety: The Foundation of Industrial Excellence

In the hustle and bustle of industrial settings, where machinery hums, sparks fly, and work reaches towering heights, safety is not just a buzzword—it’s a way of life. At its core, safety means ensuring that every worker returns home unharmed at the end of the day. It’s about protecting lives, preserving livelihoods, and upholding the integrity of our industry.

Key OSHA Standards for Toeboards

At Intrepid Industries, we believe that knowledge is power, and when it comes to safety, it’s essential to be well-informed. OSHA, the guardian of workplace safety standards, has established specific guidelines regarding toeboards. Understanding these regulations is key to maintaining a secure work environment. Here are some key OSHA standards related to toeboards:

- OSHA 1910.23(a)(8): This standard mandates the installation of toeboards on all open-sided floors, walkways, platforms, or runways that are four feet or more above the adjacent floor or ground level.

- OSHA 1926.501(b)(1): In the construction industry, OSHA requires the use of toeboards, guardrails, or other protective barriers to prevent falling objects at construction sites.

- OSHA 1910.28(C) and 1910.29(k)(1): Employers must protect employees from falling objects.

By adhering to these standards, businesses can ensure compliance with OSHA regulations and, more importantly, create a safer work environment where the risk of falling objects is significantly reduced.

As you navigate our page on OSHA toeboard requirements, you’ll gain deeper insights into these regulations and their practical application in your industry. Together, we’ll build a safer, more secure workplace where toeboards play a vital role in protecting lives and upholding the integrity of our industry.

OSHA Toeboard Height Requirements

Safeguarding Workspaces: OSHA’s Height Standards

When it comes to toeboards, height is an important factor. To ensure comprehensive workplace safety, OSHA has established specific requirements regarding the height of toeboards. At Intrepid Industries, we understand the importance of clarity in compliance, so let’s dive into the specifics.

The Minimum Height for Toeboards

According to OSHA standards, toeboards must meet specific height criteria to be effective in preventing falling objects. The general guideline is straightforward:

- Minimum Height: Toeboards must have a minimum vertical height of three and a half inches (3.5″) from the working level’s surface. This minimum height is designed to act as a protective barrier, preventing tools, equipment, or materials from accidentally falling off elevated surfaces. It serves as a crucial line of defense, reducing the risk of injuries or damage caused by falling objects.

Application in Different Work Areas

The application of toeboards isn’t limited to a single industry or workspace. OSHA’s toeboard height requirements are applicable across various work areas, ensuring consistent safety standards. Here’s how toeboards with a minimum height of three and a half (3.5”) apply in different scenarios:

- Construction Sites: Toeboards are a staple in construction sites, where elevated work platforms, scaffolds, and walkways are common. They provide vital protection for workers on higher levels and those working below, reducing the risk of tools or materials falling.

- Manufacturing Facilities: Manufacturing floors often have elevated machinery and equipment platforms. Toeboards are essential in these settings to prevent components or tools from falling onto the production floor.

- Warehouses and Loading Docks: Warehouses and loading docks frequently involve the movement of heavy materials. Toeboards along the edges of raised platforms or loading areas keep goods secure and protect personnel.

- Maintenance and Repair: During maintenance or repair work, personnel may access elevated equipment or machinery. Toeboards maintain a safety perimeter, preventing accidents and injuries.

At Intrepid Industries, we believe that safety is a shared responsibility. By comprehending and implementing OSHA’s toeboard height requirements, businesses across industries can create safer work environments, reduce accidents, and protect their most valuable assets—their workforce.

As you explore this page further, you’ll find additional insights, practical tips, and best practices for ensuring compliance with OSHA’s toeboard standards in your specific industry or workspace. Together, we can build a safer, more secure future for industrial operations.

Toeboard Material and Design Guidelines

Building Safety from the Ground Up: The Right Materials and Design

In the world of workplace safety, every component plays a role in protecting workers from falling objects and preventing accidents. Toeboards, often overshadowed by larger safety measures, are no exception. At Intrepid Industries, we recognize the significance of toeboards and are here to guide you through the essential aspects of their material, design, and maintenance.

Materials for Durability

The choice of materials for toeboards is a critical decision, as it directly impacts their durability and effectiveness. Common materials used for toeboards include:

- Wood: Wooden toeboards are a classic choice due to their availability and cost-effectiveness. They offer decent durability but may require regular inspections and maintenance to ensure they remain solid and effective.

- Metal: Metal toeboards, often made of steel or aluminum, provide exceptional durability. They are resistant to weathering, corrosion, and wear, making them a long-lasting choice for outdoor and rugged environments.

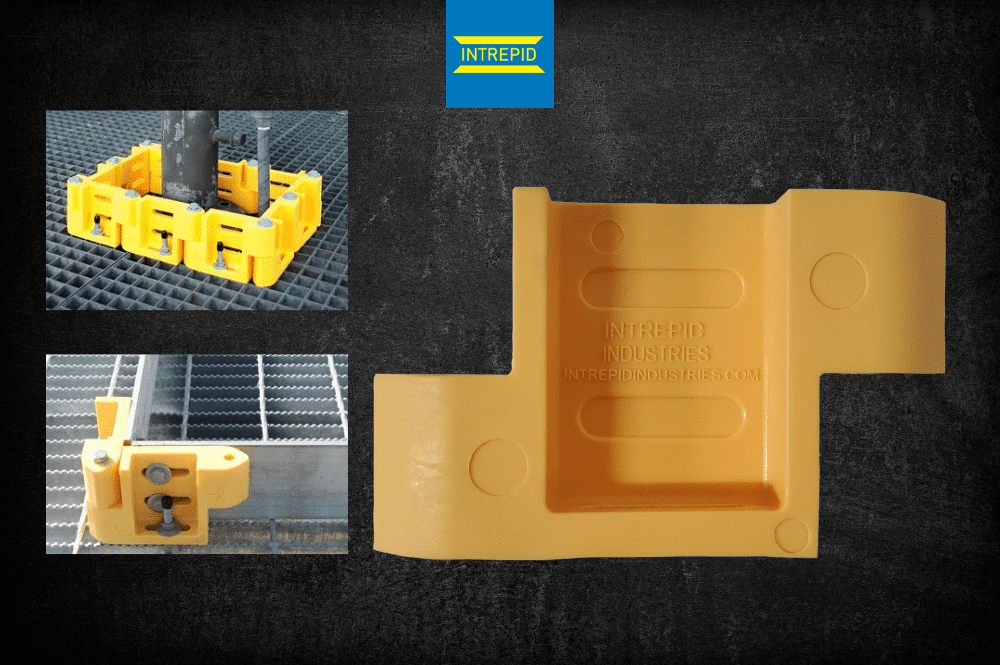

- Plastic: Plastic toeboards, like the ones from Intrepid Industries, are corrosion-resistant and easy to install. They are a practical choice for various applications and are less likely to require frequent maintenance.

The selection of toeboard material should align with the specific needs of your workplace and the environmental conditions it will face. It’s essential to choose materials that withstand the challenges of your industry while maintaining structural integrity.

OSHA’s Design Guidance

OSHA provides clear guidelines on the design of toeboards to ensure their effectiveness in preventing falling objects. Here are some key aspects of OSHA’s design guidance:

- Opening Specifications: OSHA requires toeboards to have no more than one-quarter inch (1/4″) between the toeboard and the surface and no more than one inch (1”) in or between the toeboard. These narrow openings prevent small objects from passing through while maintaining visibility and airflow.

- Solidness: Toeboards must be solid and capable of withstanding the impact of falling objects. OSHA emphasizes the importance of toeboards being secure and able to contain falling debris.

- Secure Attachment: Proper installation is paramount. Toeboards must be securely attached to the structure they are protecting. OSHA standards mandate that toeboards be able to withstand a force of at least 50 pounds (50 lbs.) applied in any downward or outward direction.

Inspecting and Maintaining Toeboard

To ensure that toeboards continue to serve their protective function, regular inspections and maintenance are essential. Inspections should include checks for loose or damaged toeboards, as well as verification of secure attachments. Any issues discovered during inspections should be promptly addressed to maintain toeboard effectiveness.

At Intrepid Industries, we advocate for a proactive approach to safety. By selecting durable materials, adhering to OSHA’s design guidelines, and implementing a robust inspection and maintenance routine, businesses can fortify their commitment to workplace safety.

Toeboard Installation and Compliance

Building a Barrier: The Art of Toeboard Installation

Installing toeboards isn’t just a matter of putting them in place—it’s about creating a solid, reliable barrier that stands between potential hazards and workplace safety. At Intrepid Industries, we understand that the proper installation of toeboards is crucial, and we’re here to guide you through the process with precision.

Proper Installation Procedures

- Secure Attachment: The foundation of effective toeboard installation is secure attachment. Ensure that toeboards are firmly anchored to the structure they are meant to protect. Properly fasten them in place using appropriate brackets, clamps, or supports.

- Correct Height: Remember the golden rule—OSHA mandates a minimum toeboard height of three and a half inches (3.5”) from the working level’s surface. Ensure that the toeboard is positioned at the correct height to serve as an effective barrier.

- No Gaps: Pay close attention to gaps between adjacent toeboards. They should be minimal to prevent objects from slipping through. OSHA specifies that toeboards should have no more than one-quarter inch (1/4″) of space between the toeboard and the surface.

- Solidness: Ensure that toeboards are solid and capable of withstanding the impact of falling objects. Rigorous materials and secure attachment contribute to the solidness of the installation.

Compliance with OSHA Standards

Compliance with OSHA standards during the installation process is non-negotiable. Here’s how you can ensure alignment with OSHA’s requirements:

- Consult OSHA Guidelines: Before beginning the installation, familiarize yourself with OSHA’s standards related to toeboards. Refer to OSHA 1910.23 and OSHA 1926.501 to understand the specific requirements applicable to your industry.

- Professional Guidance: When in doubt, seek professional guidance. Consider consulting with a safety expert or a qualified individual experienced in toeboard installation to ensure compliance.

- Regular Inspections: After installation, conduct regular inspections to verify that the toeboards remain in compliance with OSHA standards. This includes checks for secure attachment, correct height, and absence of gaps.

Common Installation Mistakes to Avoid

Avoiding common installation mistakes is as critical as following proper procedures:

- Inadequate Attachment: Failing to securely fasten toeboards to the structure can result in instability and reduced effectiveness. Ensure robust attachment to prevent potential hazards.

- Incorrect Height: Deviating from the minimum height requirement can compromise safety. Always position toeboards at the prescribed height to provide adequate protection.

- Gaps and Openings: Overlooking the size of gaps between toeboards can lead to accidents. Adhere to OSHA’s one-quarter inch (1/4″) maximum gap between the toeboard and the surface requirement.

- Using Damaged Toeboards: Installing damaged or compromised toeboards is a recipe for disaster. Always inspect toeboards for signs of wear and replace any that show structural issues.

By following proper installation procedures, ensuring compliance with OSHA standards, and avoiding common mistakes, you can create a robust barrier that enhances workplace safety and prevents falling objects from becoming hazards.

A Secure Future: Prioritizing OSHA Toeboard Requirements

At Intrepid Industries, we believe that the heart of workplace safety lies in our collective commitment to protecting each other. It’s not just about complying with regulations; it’s about safeguarding lives, preserving well-being, and upholding the integrity of our industry.

Prioritize Toeboard Safety

We encourage you to prioritize toeboard safety and compliance. By doing so, you’re not only meeting regulatory requirements but also actively contributing to a secure work environment where every worker can perform their duties without the looming threat of falling objects.

Your Safety Partner

As you navigate the complexities of toeboard requirements and workplace safety, remember that you’re not alone. Intrepid Industries is here to be your safety partner, providing insights, guidance, and solutions to enhance workplace safety.

Together, we can build a future where safety is second nature, where regulations are not burdens but beacons of protection, and where the well-being of our workforce remains our highest priority.

Ever looked at an engineering drawing and noticed how nicely everything comes together? Everything is perfect! Unfortunately, during the construction stage, that perfection quickly fades. A hole may be positioned in a specific location on the surface, but the pipe doesn’t quite line up. Options become limited once the mistake is discovered. Either the decking can be replaced or the hole size increased, typically opting for the latter.

Once the hole is enlarged, action must be taken to prevent dropped objects from falling onto the walking-working surface. With that in mind, let’s take a look at the following questions…

What is a hole, and when is it large enough to require protection? The Occupational Safety and Health Administration (OSHA) Walking-Working Surfaces standard 1910.21(b) states that a “hole is a gap or open space in a floor, roof, horizontal walking-working surface, or similar surface that is at least 2 inches (5 cm) in its least dimension.”

When the previous criterion is met, what must be done? When a hole exists, OSHA standard 1910.28(C) and 1910.29(k)(1) states that employers must protect employees from falling objects. One way they suggest doing this is by erecting toeboards, or kickplates [1910.28(C)(1)]. As defined in 1910.21(b), “a toeboard means a low protective barrier that is designed to prevent materials, tools, and equipment from falling to a lower level.”

What is the toeboard requirement? OSHA 1910.29(k)(1)(ii) states that it must “have a minimum vertical height of 3.5 inches (9 cm) as measured from the top edge of the toeboard to the level of the walking-working surface.”

Once it is identified that a toeboard is required, the following options exist:

Welding – This is the most popular, although the most expensive, option. This method requires welding metal banding to metal grating and checker plate style surfaces. Installation requires running welding leads; cutting, bending, and tacking metal banding; and painting or galvanizing. This option is also not the easiest to remove in the event of rework, repairs, or renovations.

Bonding – This is an option used on fiberglass surfaces where welding is not an option. Installation usually consists of cutting strips of fiberglass to the correct size and using the epoxy resin to join it to the surface. Installation may be difficult because there is usually insufficient surface area to get a good bond.

Fastening / Anchoring – This option may be used on all surfaces. The material used may be polyurethane links or collars, wood, metal, etc. These are usually installed by fastening hardware through the toeboard material to the surface. This is usually the least expensive option, and in the event rework or renovations are needed, this is the easiest to remove.

Now that you know what to look for, look around to see if you have any holes that need protecting!

For more information on our Intrepid Toeboards (T5) click here or give us a call at 281-479-8301.

For more information visit www.intrepidindustries.com or www.osha.gov, call (281) 479-8301 or email Paxton Guidroz direct at pguidroz@intrepidindustries.com.