Call Us Today! 281-479-8301 | 866-479-8301 | sales@intrepidindustries.com

AutomationPaxton Guidroz

Automation

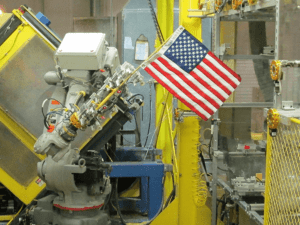

Intrepid has been using automated systems to generate products since 2000 and specializes in designing and integrating automated manufacturing systems. Although, focus is in material handling and tooling, installation of various robotic arms for multiple applications is available.

Having an in-house machine shop allows for rapid development of custom end of arm tools (EOAT) without having to rely on third party vendors. These tools are essential in order for the robot to interact with your process. This advantage gives flexibility to provide the perfect solution for you.

There are an endless number of robots on the market that are designed to fit numerous manufacturing environments.

The most popular types of robotic arms are:

- 6 Axis Robots – The most versatile robotic arm, great for material handling, welding, pick and place, and machine tending applications. They have 6 independent joints that work together to move and work in almost any orientation.

- Collaborative Robots – Designed with safety in mind, these robots can be used to work alongside workers to assist in all sorts of tasks that would otherwise be dangerous or monotonous.

- Specialized Robotic Systems – These robots are generally very good at one type of task, like lifting heavy objects, moving very quickly or doing extremely simple repetitive motions.

If you are unsure, let us help you choose the robot most suited for your application.

Please complete this FORM to request additional information or contact us at: lmuthu@intrepidindustries.com.

UDG Blade Automation

UDG Block Automation

Automated Gates

UDG Hinge Automation

UDG Pin Automation

8 Foot Automated Gate